Role Of Oxide Ceramics In Energy Management

Candidate massachusetts institute of technology december 22 2015.

Role of oxide ceramics in energy management. Energy management procedures and energy awareness training programs within the establishment. Their development and improved understanding are still driving improvements in the safety efficiency and reliability of nuclear power where it remains the leading source of low carbon energy and these are having beneficial knock on effects related to nuclear power s. There are both coarse and fine grained varieties. Ceramics have played a vital role in the rise of nuclear power since its inception in the mid 20th century.

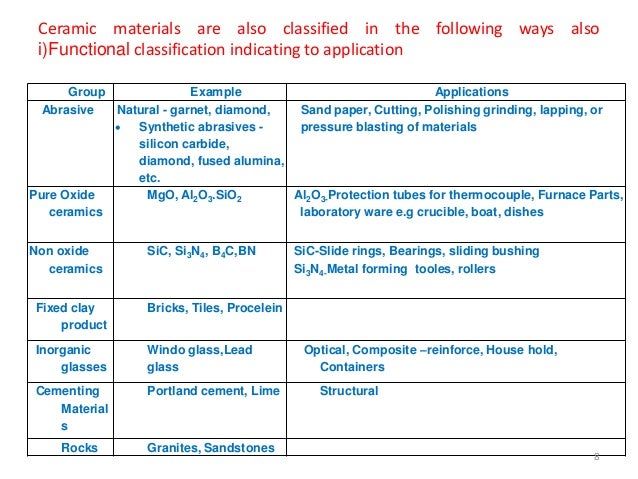

Ceramic composition and properties atomic and molecular nature of ceramic materials and their resulting characteristics and performance in industrial applications. Ceramic materials for. Within the energy sector wear resistant ceramics are also used in machinery for energy production including bearings valves seals spheres pumps sheaths and tubes for wind turbines gas turbines oil and gas extraction equipment and other systems. Chemical engineering university of toronto 2012 s m.

Hydrophobicity of rare earth oxide ceramics and their application in promoting sustained dropwise condensation and corrosion and fouling mitigation in hydropower systems by sami khan b a sc. Existing baseline information and reports are useful to get consumption pattern production cost and productivity levels in terms of product per raw material inputs. Examples of applications for aluminum oxide al 2 o 3 advanced ceramics are heavy duty forming tools substrates and resistor cores in the electronics industry tiles for wear protection and ballistics thread guides in textile engineering seal and regulator discs for water taps and valves heat sinks for lighting systems protection tubes in. Oxide ceramics are inorganic compounds of metallic e g al zr ti mg or metalloid si elements with oxygen.

The kiln builds the glaze from these it does not care what material sources what oxide. Alumina ceramic is relatively inexpensive readily obtained and has metallization schemes compatible with the user friendly 94 to 97 compositions that can be commercially obtained. 2001 studied the role of the dispersant mfo and pe and the ysz powder dimensions on the slurry rheology and the effect on green as well as sintered densities of tape cast ysz. Aluminum oxide ceramic or alumina is the preferred nonmetal choice for many structural ceramic components and high voltage insulators.

Usually they are metal oxides that is compounds of metallic elements and oxygen but many ceramics. The audit team should col lect the following baseline data. The energy required for the oxide ion migration from one site to the neighboring unoccupied equivalent site must be. Oxides can be combined with nitrogen or carbon to form more complex oxynitride or oxycarbide ceramics.

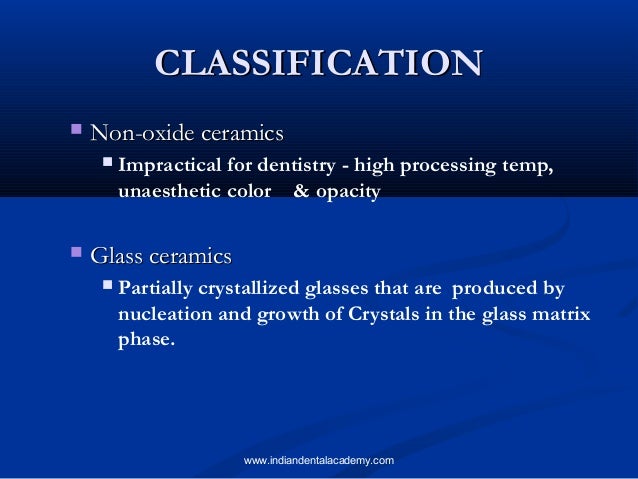

Industrial ceramics are commonly understood to be all industrially used materials that are inorganic nonmetallic solids. The main applications of ceramics and glass in energy are illustrated in the table below. Ceramic oxide periodic table.