Raw Material Preparation And Forming Of Ceramic Tiles

Preparation of a powdered ceramic material and a liquid usually clay and water into.

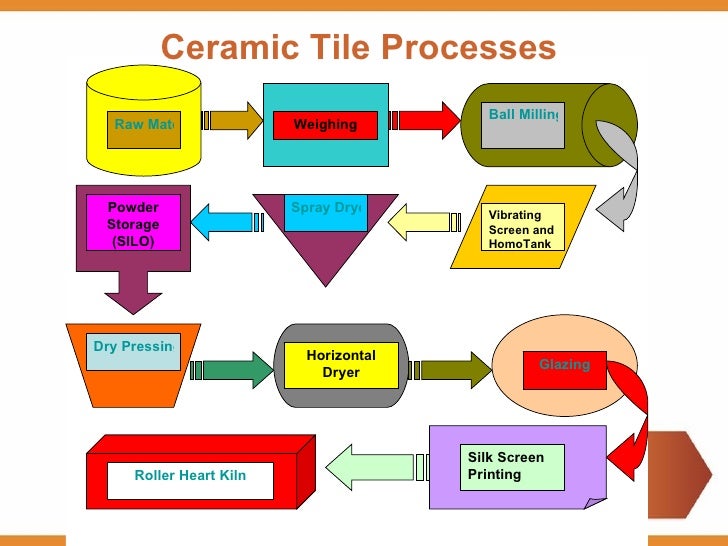

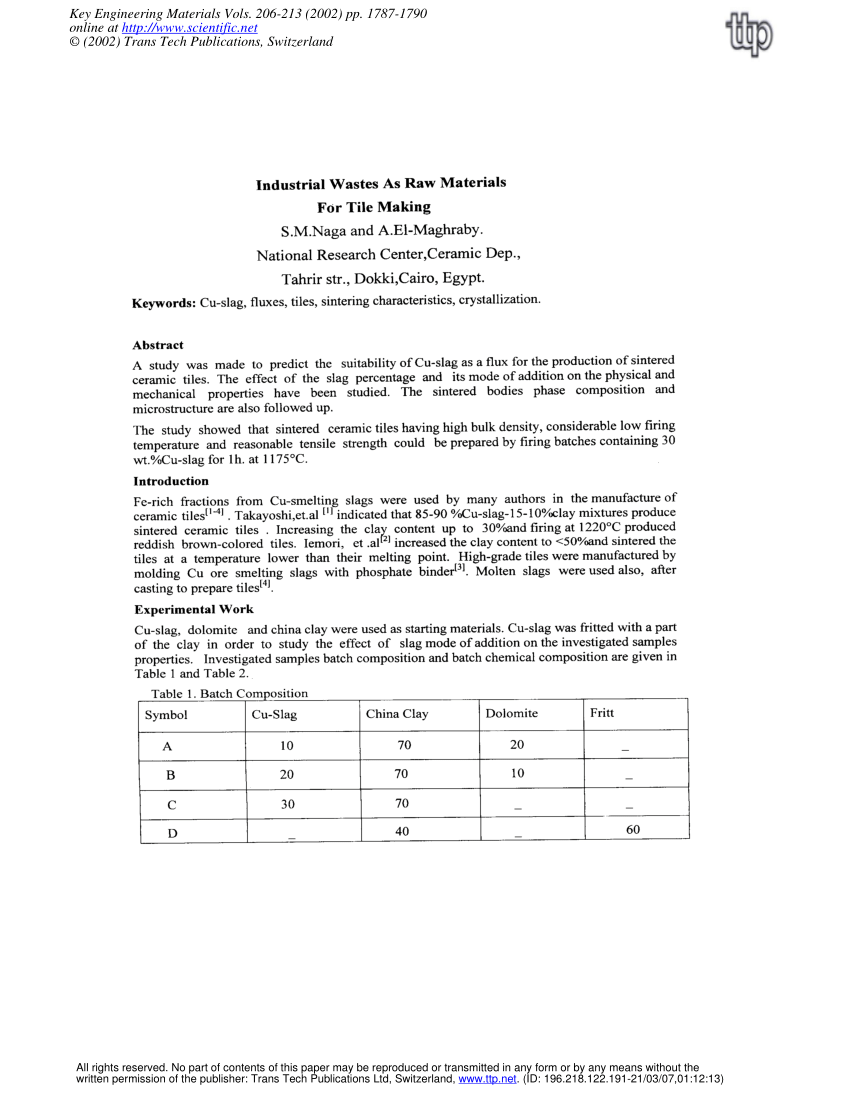

Raw material preparation and forming of ceramic tiles. Preparation of raw materials. From each raw material of the base composition about 10 kg were provided in the form of lumps. We will discuss all the production process methods used in the ceramic industry. Consequently the aim of this work is to use egyptian raw materials in order to produce a porcelain tile which satisfies the level required by the standards.

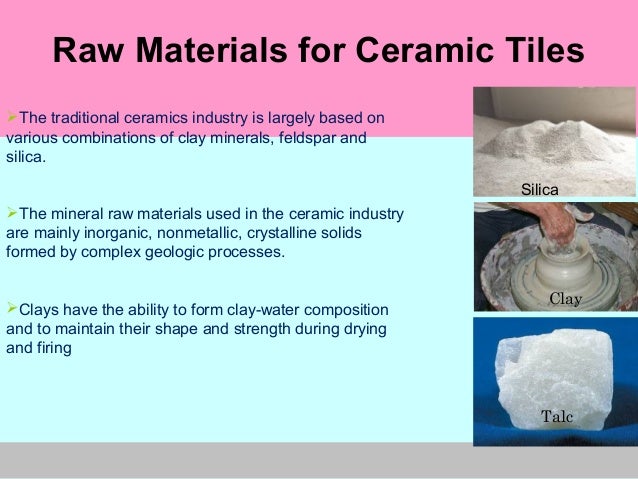

Ceramic raw materials have different uses. 1 for many ceramic products including tile the body composition is determined by the amount and type of raw materials. Kaolin is a form of clay and. Preparation of raw materials and shaping of ceramic tiles introduction.

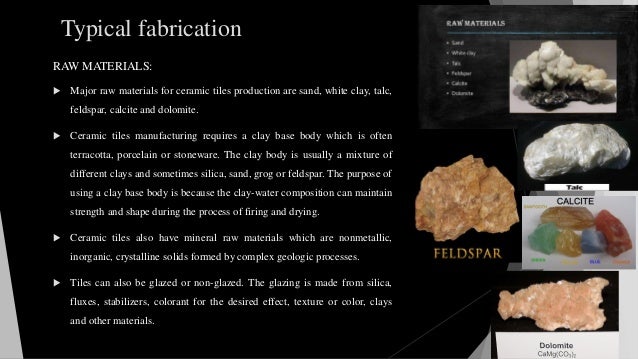

Among the uses of ceramic raw materials it is just right to be partnered with the best ceramic raw material supplier. Feldspar is a rock forming material found in the earths crust. There are different production process methods are used in the ceramic production process. Of raw material preparation shaping raw drying heating grading and packing assures each ceramic tile low maintenance longevity long term luster and safe shipment to anywhere in the country.

Raw materials preparation chapter 1. The raw materials also determine the color of the tile body which can be red or white in color depending on the amount of iron containing raw materials used. Raw materials for the production of ceramic tiles mariano paganelli first part. A raw gob of glass a parison or temporary shape is formed by.

In addition some raw materials for brick and tiles manufacture are transported over long distances which add to the transportation component of material production. Grog is a granular material made from crushed brick. Ceramic tiles are economical to produce because of the raw materials used are easily available mined ceramic minerals. The contents improve strength durability and toughness of the ceramic body.

Body formulation and grinding. 2 2 formation of granules 2 3 powder separation 3. We at sodis pour le commerce supply reliable ceramic raw materials that. Our cladding system of fixing and fastening.

The term ceramic forming describes the process of production of ceramic components from natural or synthetic raw materials. The primary raw material for the tile production is clay quarts and feldspar. To ensure that whatever you use it for e g. Ceramic tile will be made with supreme quality and durability.

They are classified based on their properties. Embodied energy of fired clay bricks and that of ceramic tiles have been estimated to be about 3 gj ton and 12 gj ton respectively hammond and jones 2011. Silica is a source of quartz. They were crushed and ground.