Pvb Laminated Glass Process

Monsanto developed a process to put a gradient colour band on the automotive interlayer and began offering it commercially in 1951.

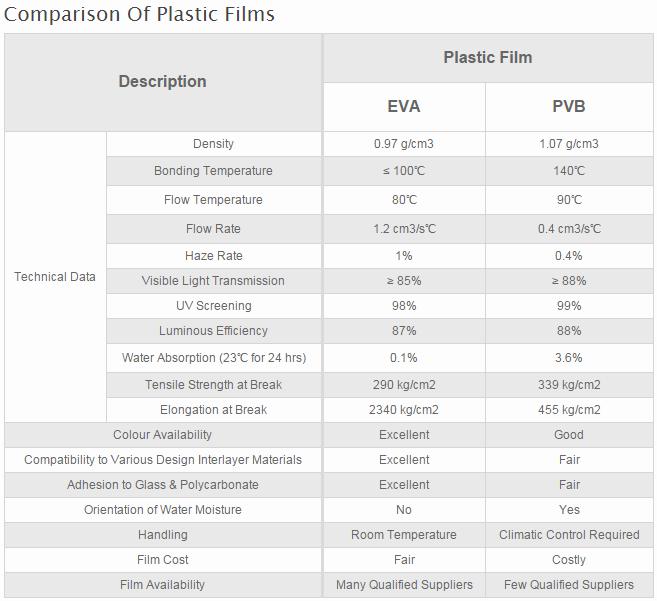

Pvb laminated glass process. Eva is challenging current pvb as a laminated material because. The trosifol sc monolayer is an acoustic pvb film that combines the sound insulating features of multiple glazing applications with traditional pvb film. By the early 1950s architectural use of laminated glass began to increase and coloured interlayer products were introduced for this application. 23 4 2020 riku färm advice glass processing glass quality interlayer laminated glass prol pvb quality technology top story as the name suggests laminated glass is composed of multiple layers of glass with an interlayer in between to hold the panes together.

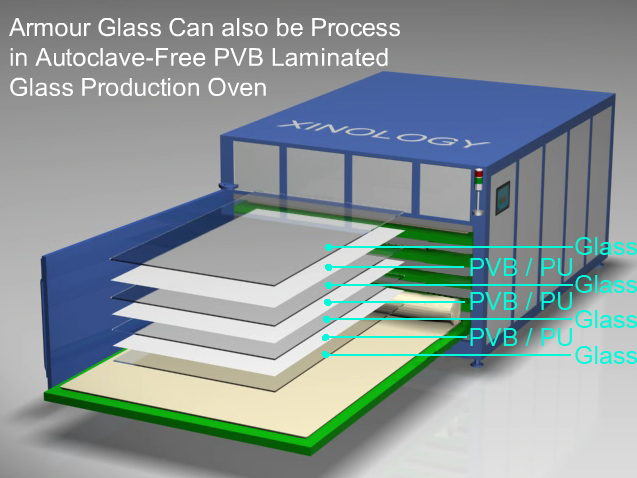

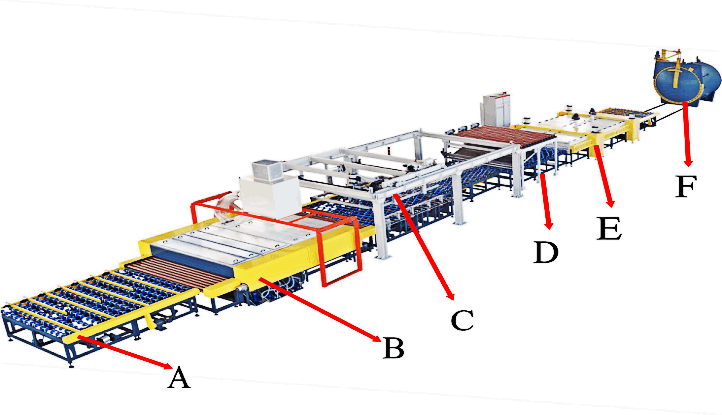

Here i want tell you the. Pvb laminated glass is manufactured by combining two or more annealed or heat treated glass sheets bonded with one or more of pvb interlayers and subjected to heat and pressure in order to ensure perfect adhesion between the constituent elements. Keep the glass clear and put it in the machine the machine takes the glass up. Laminated sound control glass.

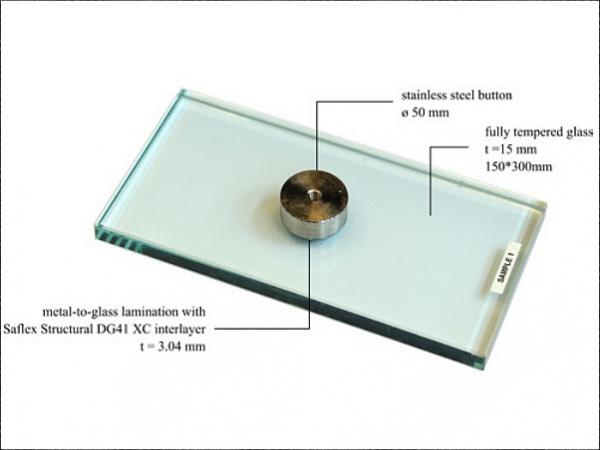

The film spread on the middle of two pieces of glass. The interlayer keeps the layers of glass bonded even when broken and its high strength prevents the glass. Pvb has been the reference material for the glass lamination on building construction and transportation industries for many years. Pvb laminated glass is produced through the use of a heat and pressure process during which a flexible interlayer is sandwiched between layers of glass.

Ethylene vinyl acetate eva film and polyvinyl butyral pvb film are two different polymer materials that can be used for glass laminated structures. Generally the interlayer has a. Laminated safety glass produced with trosifol sc monolayer offers an improvement of 5 db in the sound insulation value as compared to float glass of the same thickness. Laminated glass is produced using one of two methods that can result in either poly vinyl butyral pvb laminated glass or cast in place cip laminate.

Trade names for pvb films include kb pvb saflex glasnovations butacite winlite. It is prepared from polyvinyl alcohol by reaction with butyraldehyde the major application is laminated safety glass for automobile windshields. 2 wait for the second piece of glass and then the first piece of the bottom and calibration. Polyvinyl butyral or pvb is a resin mostly used for applications that require strong binding optical clarity adhesion to many surfaces toughness and flexibility.