Processing Of Particulate Ceramics

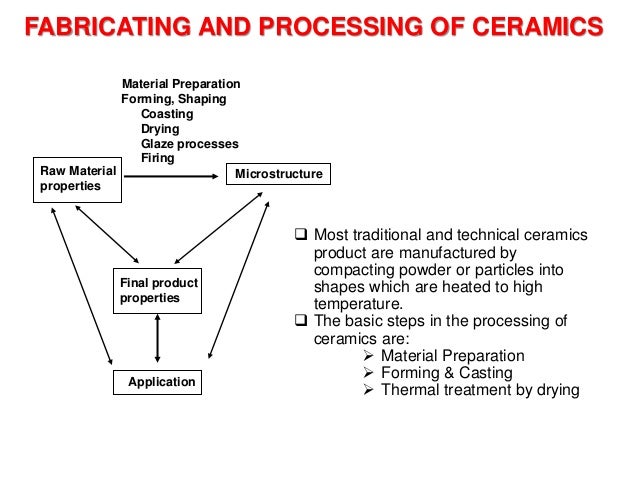

Ceramic processing the higher performance of ceramics is the result of strict contr ol of purity composition microstructure and processing.

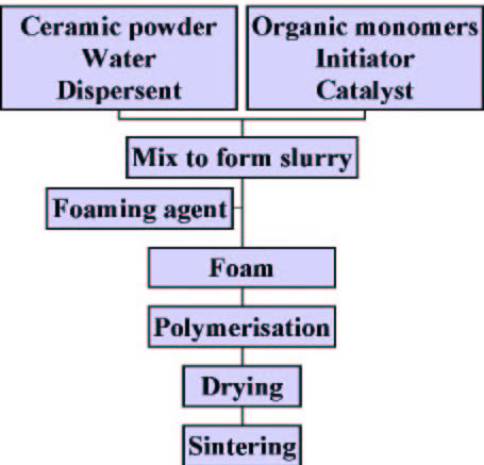

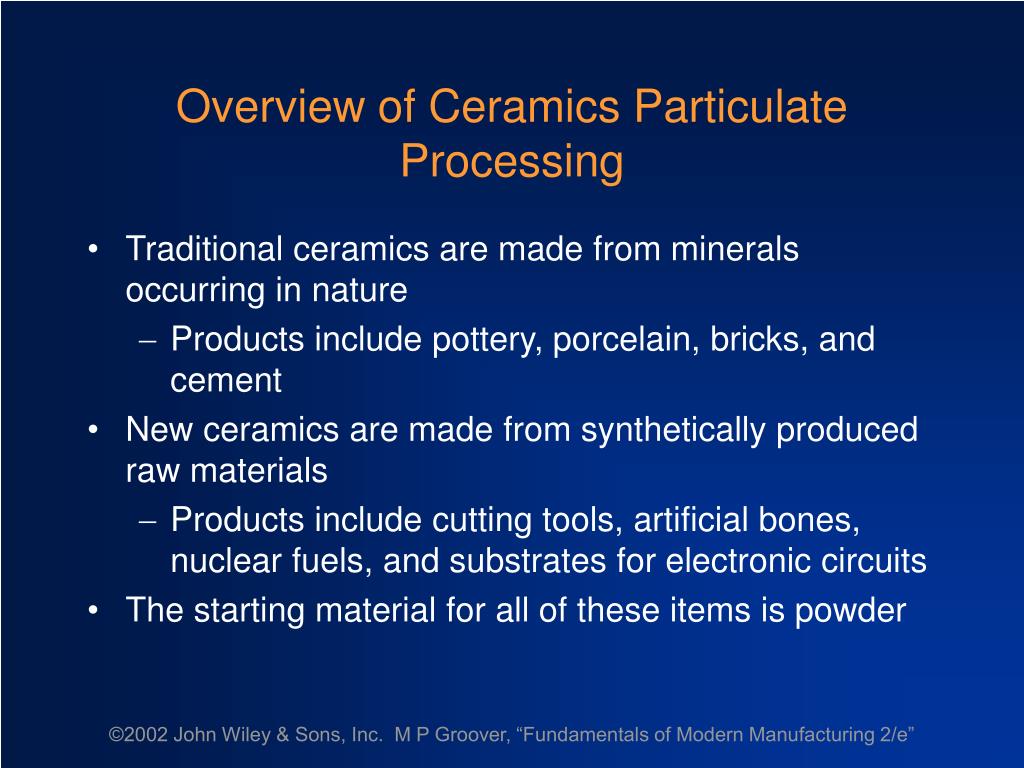

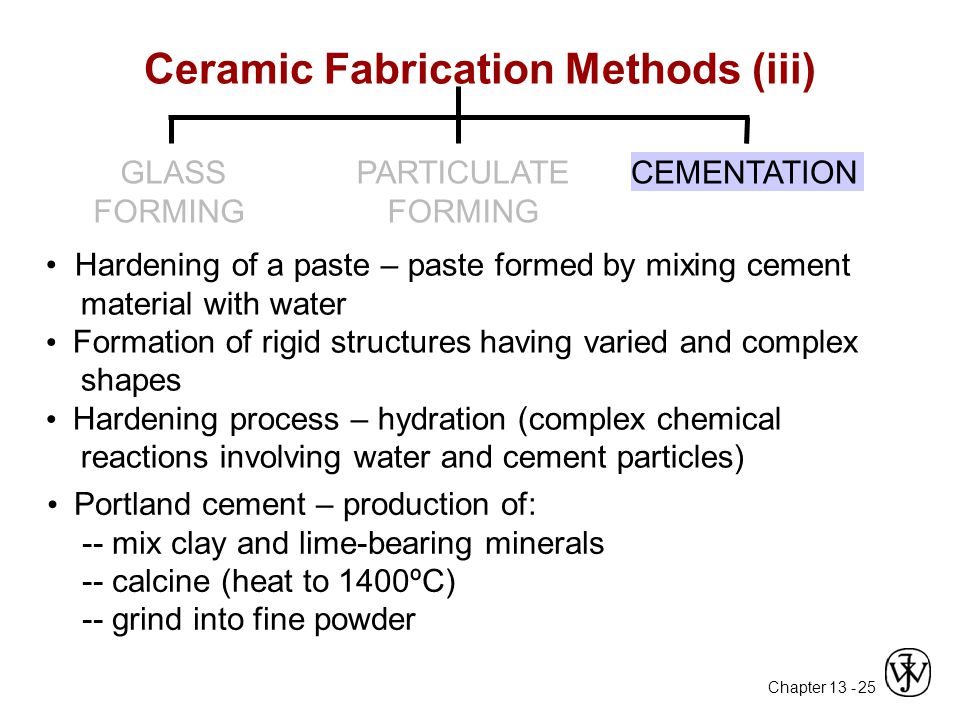

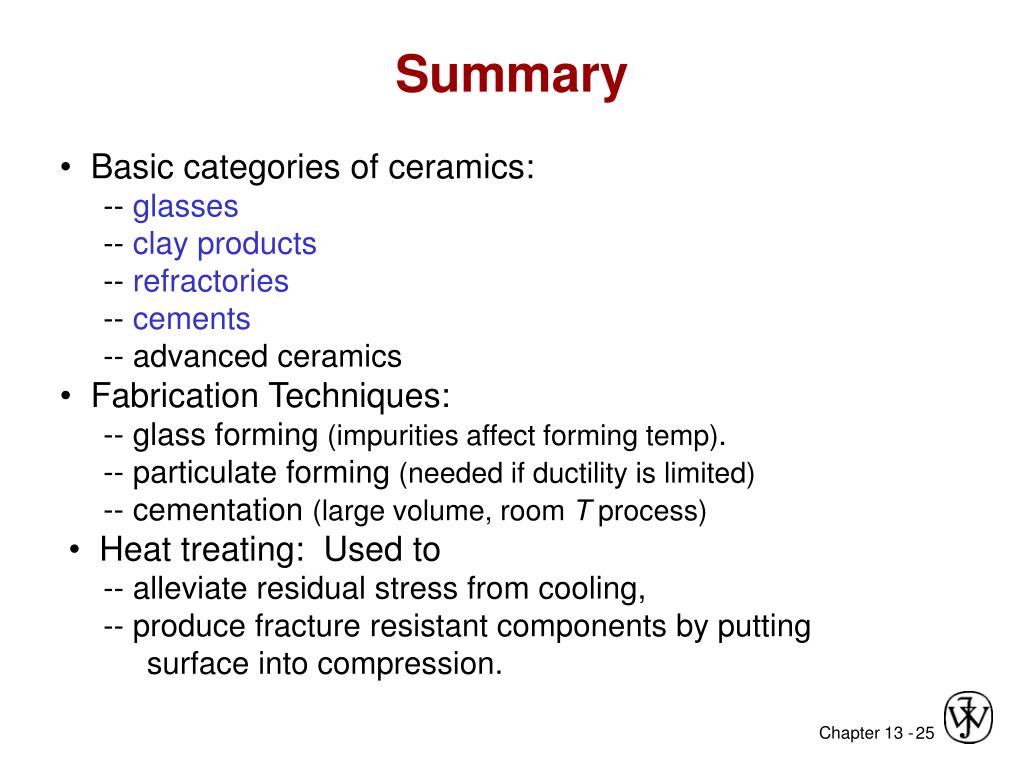

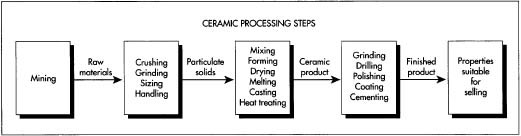

Processing of particulate ceramics. From the chemical point of view ceramics are characterized by ionic or covalent bonding providing the typical outstanding ceramic properties such as high hardness high young s modulus and a very high melting point. Particulate forming needed if ductility is limited cementation large volume room t process heat treating. Most often pug mills are the preferred piece of machinery used in this step of the process when dealing with dry mixes. The origins of the sol gel process date back to the mid 1800s 7 8 when the first observation of the chemical reaction was made.

Blowing pressing drawing fiber forming and sheet forming. Glass forming particulate forming and cementation. It is also important to add binders or plasticizers as well. In glass forming processes the raw materials are heated until they melt.

The purpose of ceramics processing to an applied science is the natural result of an increasing ability to refine develop and characterize ceramic materials. Even though originally the sol gel technique was developed for ceramics processing it has found many applications outside ceramics. Glasses solidification processing the solidification processes for glass are covered in a different slide set the particulate processes for traditional and. The fabrication methods of ceramics are classified in three categories.

Clearly both particulate and whisker composites are conceivable by solid state precipitation after solidification of the melt. Ebelman in 1846 observed the formation of transparent materials from the slow. Mixing to obtain a more chemically and physically homogeneous material prior to forming the constituents of the ceramic powder are combined using the method of mixing or blunging. This book covers fundamental issues encountered in colloidal processing nano less than 0 1 micron micro from 0 1 to 5 micron and macro larger than 5 micron particulate systems and at the same time explore applications for these developments.

Traditional ceramics particulate processing 2. Particulate processing of metals and ceramics free download as powerpoint presentation ppt pptx pdf file pdf text file txt or view presentation slides online. Ceramic processing is used to produce commercial products that are very diverse in size shape detail complexity and material composition structure and cost. The following five minute video highlights.

There are also some opportunities to utilize melt processing for fabrication of ceramic particulate whisker and short fibre and continuous fibre composites. New ceramics particulate processing 3. Types of ceramics and their processing ceramic materials divide into three categories. There are five glass forming processes.