Process To Create A Dense Ceramic Pellet

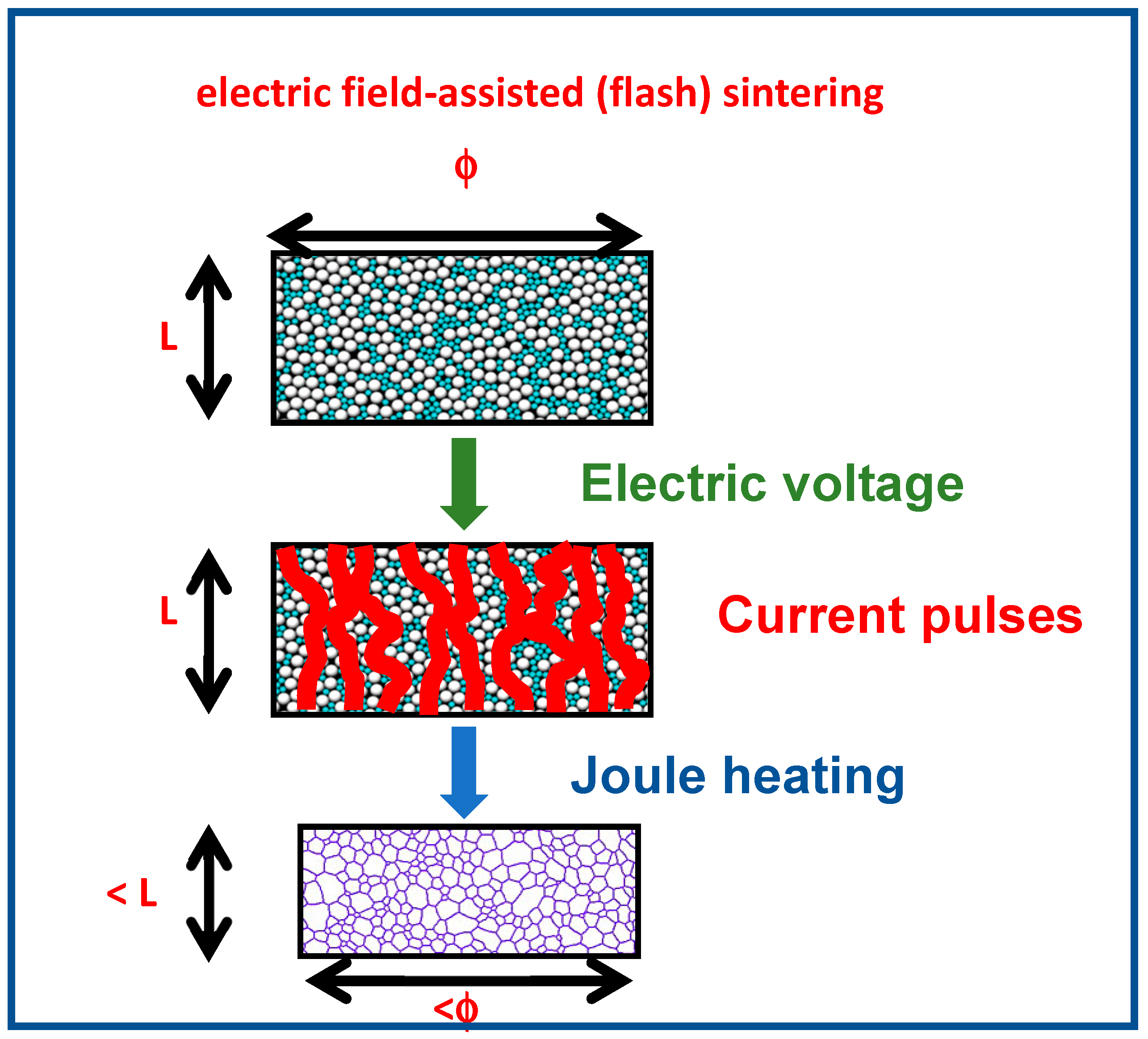

Press them at 50 to 70 mpa and sinter them at 1400 c in argon or helium for 50 to 60 minutes and you would have dense compact with 90 to 93 density.

Process to create a dense ceramic pellet. This process is used for. Sintering green compacts made of such granules gives highly dense and defect free pellets that have a very homogeneous u pu spatial distribution thus improving the fuel characteristics. Binders are used to adjust the. They also serve as a filler to make up for volume lost during the coarse and medium grit steps.

This would wholly depend on the process steps you will be performing in forming your ceramic body as well as the density of the material you want to achieve. To make a dense ceramic pellet. Chipping of the woods using the drum chipper this entails processing of the used to ensure they have required sizes that is considered to be less than 6mm. To make a dense ceramic pellet.

In their nuclear related functions ceramics are of major importance. The use of binders is crucial for the manufacture of ceramic and metallic products via powder technological process routes. Not only are the pellets more energy dense they are also easier to handle and use in automated feed systems. Nuclear ceramics ceramic materials employed in the generation of nuclear power and in the disposal of radioactive nuclear wastes.

2 4 tons pellet production process. Large ceramic pellets work great for delivering grit or polish to difficult to reach surfaces. Read one of my paper sintering of al203. Pellets are heated and mechanically mixed in a long chamber forced through a small opening and cooled with air or water.

They improve the tumbling action when you have larger rocks in the barrel. These advantages when combined with the sustainable and ecologically sound properties of the fuel make it very attractive for use. The making of the pellets undergoes the following steps. Biomass pellets are generally a superior fuel when compared to their raw feedstock.

The resin pellets are heated and mechanically mixed in a chamber and then forced under high pressure into a cooled mold. It is a similar process to forming a wood pellet but on a larger scale. How to make pellets step by step. Since the beginning of nuclear power generation oxide ceramics based on the fissionable metals uranium and plutonium have been made into highly reliable fuel pellets for both water cooled and.

A popular biomass briquette emerging in developed countries takes a waste produce such as sawdust compresses it and then extrudes it to make a reconstituted log that can replace firewood. These angle cut cylinders are approximately 3 8 9mm diameter x 5 8 16mm long.